Glimpses into IMPRESS part 6

Here is a glimpse into crystallization studies that have commenced recently. These contributions serve to demonstrate that crystallization methods are promising alternatives for separation.

Investigation of melt crystallization for production of ultra pure glycols and sugar alcohols

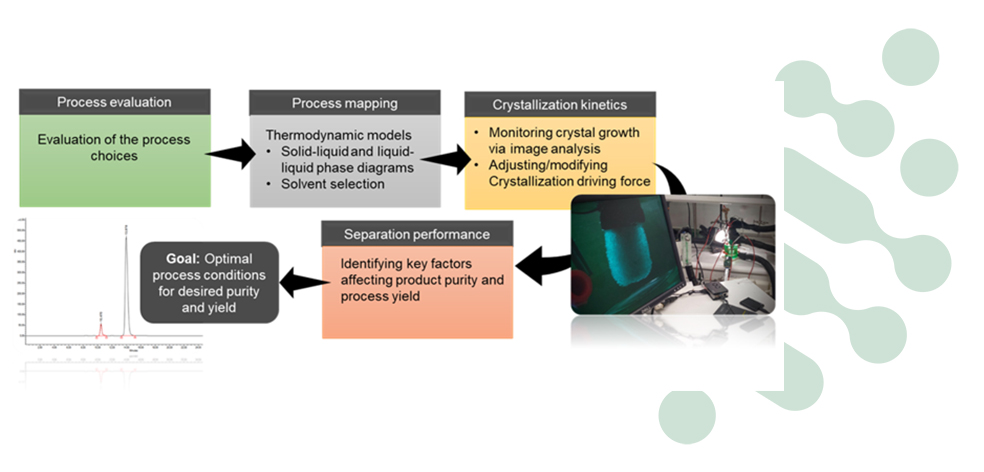

Purification of diols and polyols derived from renewable biomass resources in the Dawn upstream process is an important step in the production of high-quality, sustainable biochemicals. Our research at Aalto University focuses on melt crystallization process for purification of these products with the goal of producing high-purity end products or raw materials for other industrial applications.

Melt crystallization offers benefits in terms of separation of close boiling, azeotrope forming and heat sensitive compounds. For instance, the research conducted on the purification of azeotrope forming mixture of MEG showed that melt crystallization under controlled condition with the use of a proper additive significantly enhanced the purification through a single crystallization stage. Progress has been made in the purification of a high viscosity and heat sensitive product using the principles of kinetics crystallization and thermodynamics of studied diols. The research ultimately leads to the optimization of the crystallization process and improving downstream purification performance and product quality.

For more information, please have a look at the new publication from Aalto University ‘Purification of monoethylene glycol by melt crystallization‘ by Mitra Ila and Marjatta Louhi-Kultanen.

Studying purification and separation of Xylitol with crystallization

Xylitol has many interesting applications in the food and pharmaceutical industries. The increase in these markets has led to intensive research, with the aim of developing a cost-efficient xylitol production process.

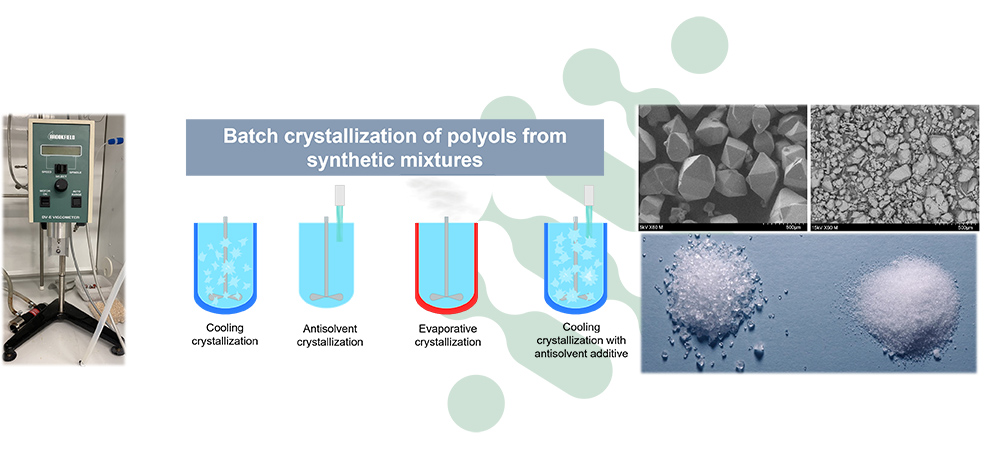

Xylitol exists naturally in fruits and vegetables, but its extraction from these sources is difficult and uneconomic due to low concentration. Xylitol can also be obtained from wood. The biotechnological production of xylitol using yeast cells has been investigated as an alternative to the chemical process. Crystallization is widely used for xylitol recovery because it allows pure polyol with solid consistency to be obtained from relatively impure solutions in a single step. Aalto has focused on their studies on investigating various crystallization methods (batch cooling, semi-batch evaporative, semi-batch antisolvent crystallization, and combined semi-batch antisolvent and batch cooling crystallization) for xylitol to achieve uniformity in terms of crystal size and shape.

For more information, please have a look at the new publication from Aalto University ‘Batch Crystallization of Xylitol by Cooling, Evaporative, and Antisolvent Crystallization‘ by Anna Zaykovskaya and Marjatta Louhi-Kultanen.